TBF’s core technology is its patented barrier material and barrier stack technology as this governs the life and reliability of electronic devices deposited on flexible substrates.

The performance of devices like organic light emitting diodes (OLEDs) and solar cells is sensitive to moisture because water and oxygen molecules seep past the protective plastic layer over time and degrade the organic materials that form the core of these products. Current commercially available films used to protect these materials have a barrier property or water vapor transmission rate of about 10‐3g/m2 per day, or one thousandth of a gram per square meter per day at 25°C and 90% relative humidity (RH). However, the ideal film for organic devices would require a barrier property of better than 10‐6g/m2/day at 39°C and 90% RH, or one millionth of a gram per square meter per day.

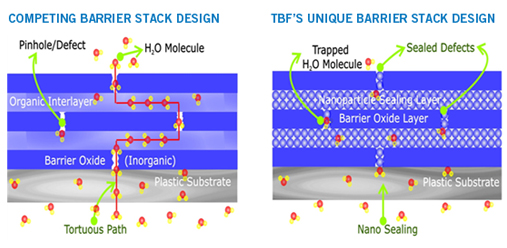

Defects such as pinholes, cracks and grain boundaries are common in thin oxide barrier films when fabricated onto plastic substrates. These defects cause a ‘pore effect’, where oxygen and water molecules are able to seep through and penetrate the plastic barrier. Current barrier technologies focus on reducing these defects by using alternate organic and inorganic multi‐layers coated on plastic. These multiple layers “stagger” corresponding pores in adjacent layers and create a ‘tortuous’, lengthy pathway for water and oxygen molecules, making it more difficult to travel through the plastic.

In contrast, TBF has taken an innovative approach to resolve the ‘pore effect’ by literally plugging the defects in the barrier oxide films using nanoparticles. This reduces the number of barrier layers needed in the construction of the barrier film down to two layers in this unique nanoengineered barrier stack. TBF’s barrier stack consists of barrier oxide layers and nanoparticulate sealing layers. The nanoparticles used in the barrier film have a dual function ‐ not only sealing the defects but also actively reacting with and retaining moisture and oxygen. The result is a breakthrough moisture barrier performance of better than 10‐6g/m2/day, or one millionth of a gram per square meter per day, which surpasses the requirements for flexible organic device substrates. The barrier film also has a lag time of more than 2,300 hours at 60°C and 90% RH (i.e. the time required for moisture to pass through the barrier film under those conditions).

TBF’s barrier stack design ensures that whatever moisture and oxygen that manages to penetrate into the film via cracks and pinhole defects would be absorbed and/or reacted with the nanoparticulates that is incorporated into the barrier material. This will ensure that the barrier films containing this material technology be of superior quality.

TBF is able to provide 2 products for the following applications:

- Solar: with barrier properties of 10‐4g/m2/day at 39°C and 90% RH

- OLED display or lighting: with barrier properties of 10‐6g/m2/day at 39°C and 90% RH

Source: http://www.tera-barrier.com/technology.html